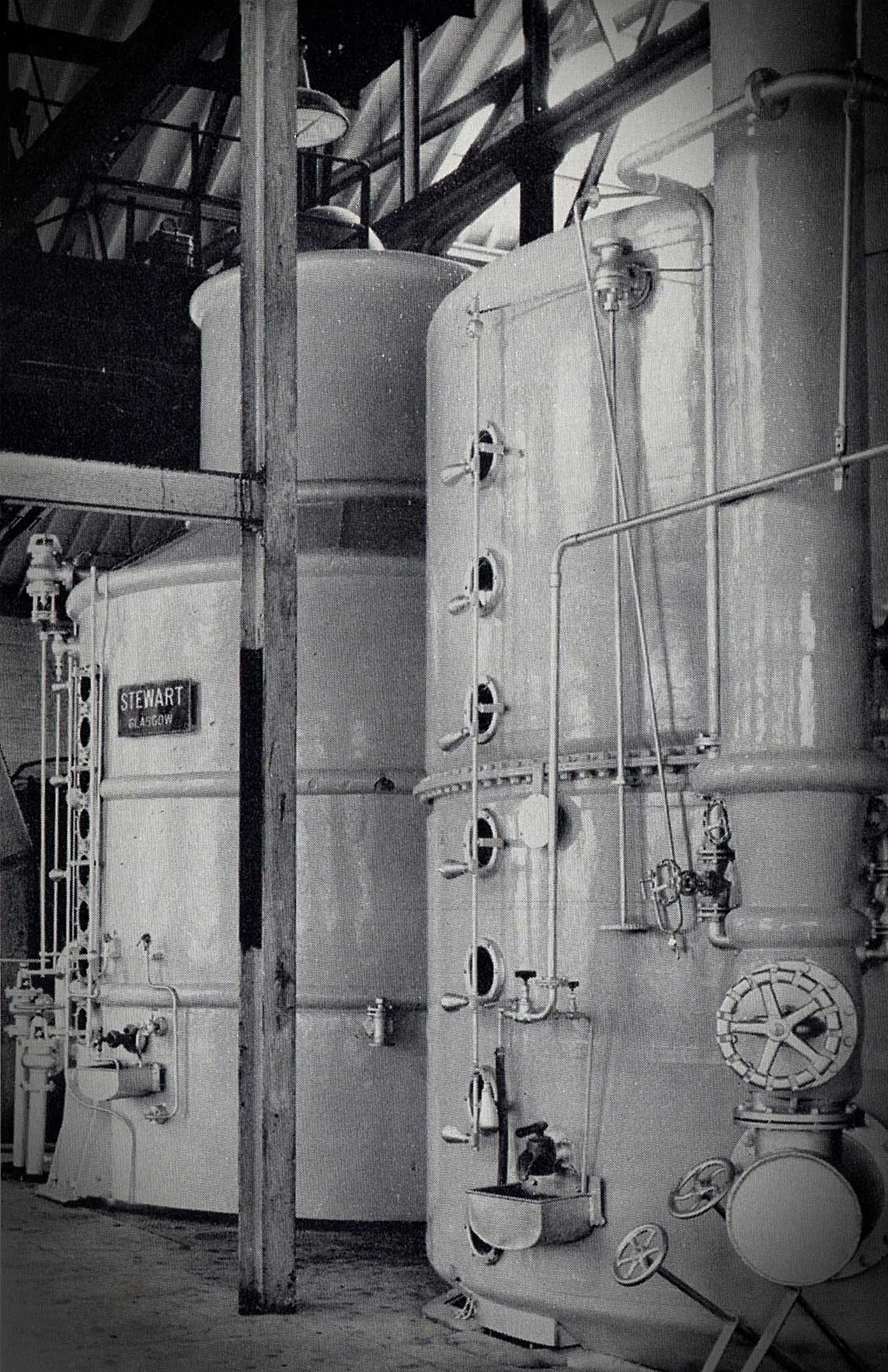

In the 1930’s the Pan Floor Manager was the most powerful man in the Home Grown Sugar (beet) factories, and a seven year apprenticeship had to be undertaken to learn how to boil sugar. That power had long gone in the 1960’s and it took me about a month to learn how to run a Pan to make sugar. A sugar boiler ran three Pans at once, which could be hectic on timing. Today the process is computer operated.

PLEASE PRESS THE ARROW BUTTON ABOVE TO HEAR THIS POEM

C-R-A-C-K the bleed on the Pan’s suction line

then open the main to the stolen air’s roar,

swirl the feed tap to its end stop

charging the vessel with evaporated juice.

When liquid licks at the lowest sight glass

slam shut the feed – then summon the skill.

Inch the steam valve’s knurled wheel

until the trapped juice boils in vacuum.

Patience – wait, – wait – wait –

for the juice to thicken and crawl

across the glass portal to airless space.

Slide the sampler within its tight seal

probe the trembling mass, twist, withdraw –

your wetted hand strokes its capture,

the only human touch required.

If syrup strings between finger and thumb

it‘s time to transmogrify to crystal.

The trigger-shock is sugar, finely ground,

a handful at the sample-cock’s curved mouth.

Fast Open Fast Close — the vacuum sucks it in,

a catalytic magic, fine crystals now emerge

throughout the altered mass; ‘Massecuite.’

You have inseminated sugar.

Like life newly formed, the crystals grow,

tightly controlled, over several hours —

fed now with juice, or water for control.

Liquid starved Massecuite will thump

and lump in torment on the glass,

a heavy pulse, a giant’s beating heart,

but misjudge correction with excess feed

and crystals will drown quietly in syrup.

Get it right, thirty tons slides in silence through the drop door,

Get it wrong, and cringe at the splatter of gigantic diarrhoea.

Empiric wisdom – consumption and construction need equal care.